ICC provides complete turnkey services for your project. From initial conception to start-up of the facility, we can assist you every step of the way.

Engineering & design services

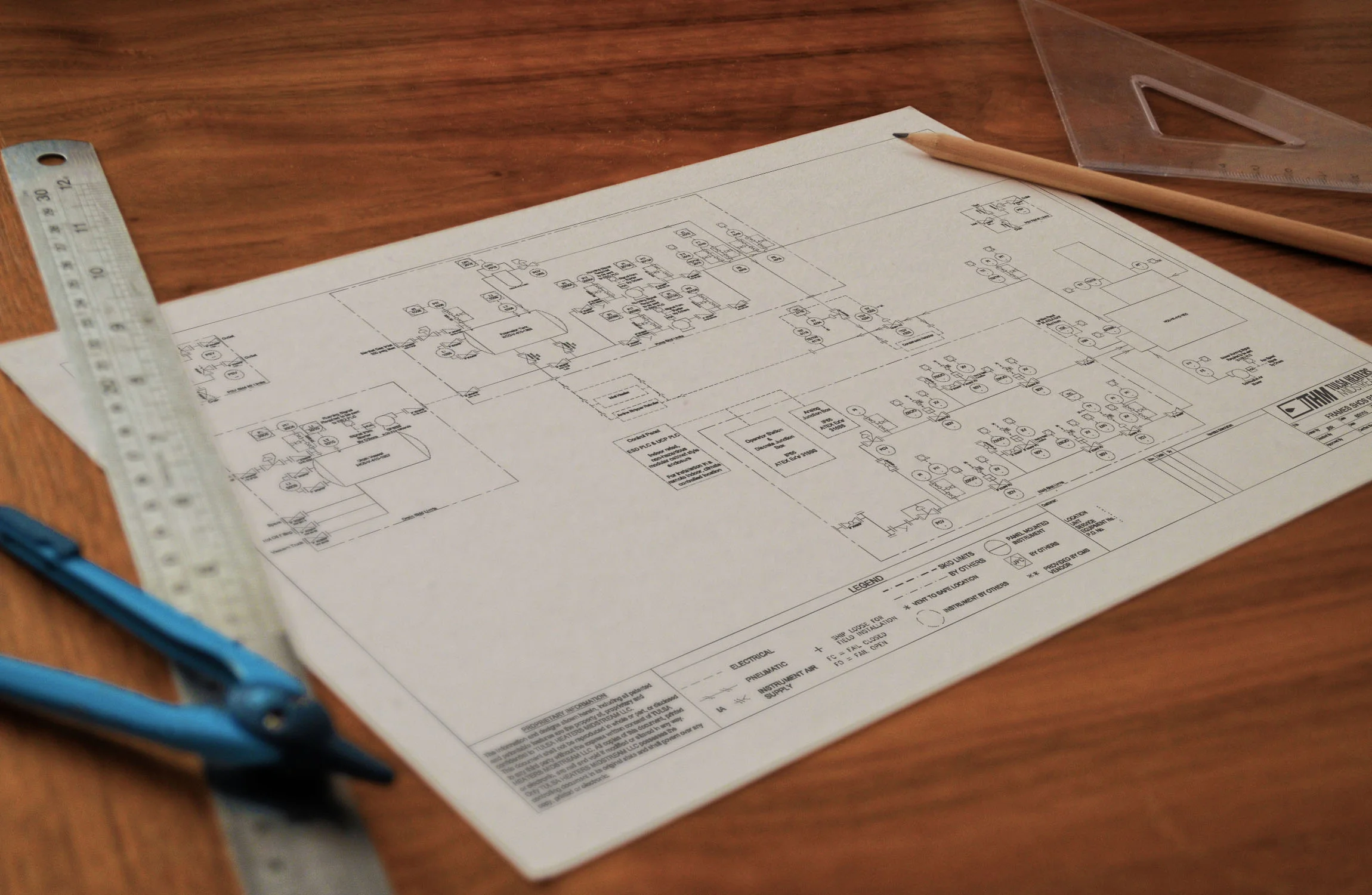

ICC's engineering and design staff is dedicated to helping our customers succeed by utilizing integrated engineering and design tools. From CAD to PLC and DCS configuration, our team can provide solutions which maximize your efficiency and minimize risk and cost impacts. ICC utilizes the latest technology in drafting software, with experience in electrical, instrumentation and piping, as well as small skid structural design. This experience allows us to efficiently design projects to meet the customer's needs.

ICC offers up front engineering services (FEED) to support customers cost benefit analysis for capital and maintenance projects. Up front engineering can reduce the project risk by providing a clear scope definition package which includes plans and basic design information.

ICC can also provide detailed design, engineering, and programming support services for automation, electrical, and instrumentation projects. Our team has experience in specifying, scoping, and detailing industrial designs to assist in the successful installation and commissioning of new projects as well as expansions.

function testing

Function testing at the factory is usually required as part of project controls. This is usually known as a Factory Acceptance Test (FAT). ICC is fully capable of setting up and performing functional tests and documenting the results for compliance per customer requirements. We can also perform Site Acceptance Tests (SAT) upon request.

Site Assistance

ICC has performed a large number of field assistance programs utilizing our in-house team and network of contractors. ICC regularly performs the following for clients:

Field Wiring

We have the capability to field set instruments, wire them to junction boxes or PLC panels, or to tube the process connections to the instruments. ICC will work with the client on site to ensure proper installation.

We have designed and installed conduit assemblies on large process skids with as many as three levels. Skids were broken down for shipping. Each of the skids was tested for continuity and in some instances Meggar testing of the wiring was done.

ICC has designed and installed cable tray applications for use in many requirements, including ATEX, CSA, SAA and NEC. We can work with third party inspectors to fully certify the connectivity system.

Field Tubing

ICC regularly installs tubing systems between instruments and process piping. These are installed utilizing ISA standards. We have installed stainless steel, copper, PVC coated copper and flourocarbon systems.

heat tracing

In many process skids heat tracing is required. ICC has the capability of designing heat trace systems to specific requirements. We have designed and installed many systems using a variety of manufacturers such as Nelson Heat Trace and Thermon.

Start-up Assistance

Our clients often have manpower restraints within their companies or simply cannot afford to have their personnel on site for considerable lengths of time. ICC offers assistance in this area, providing personnel to help start-up a variety of equipment with a specialization in fired equipment.